Menu

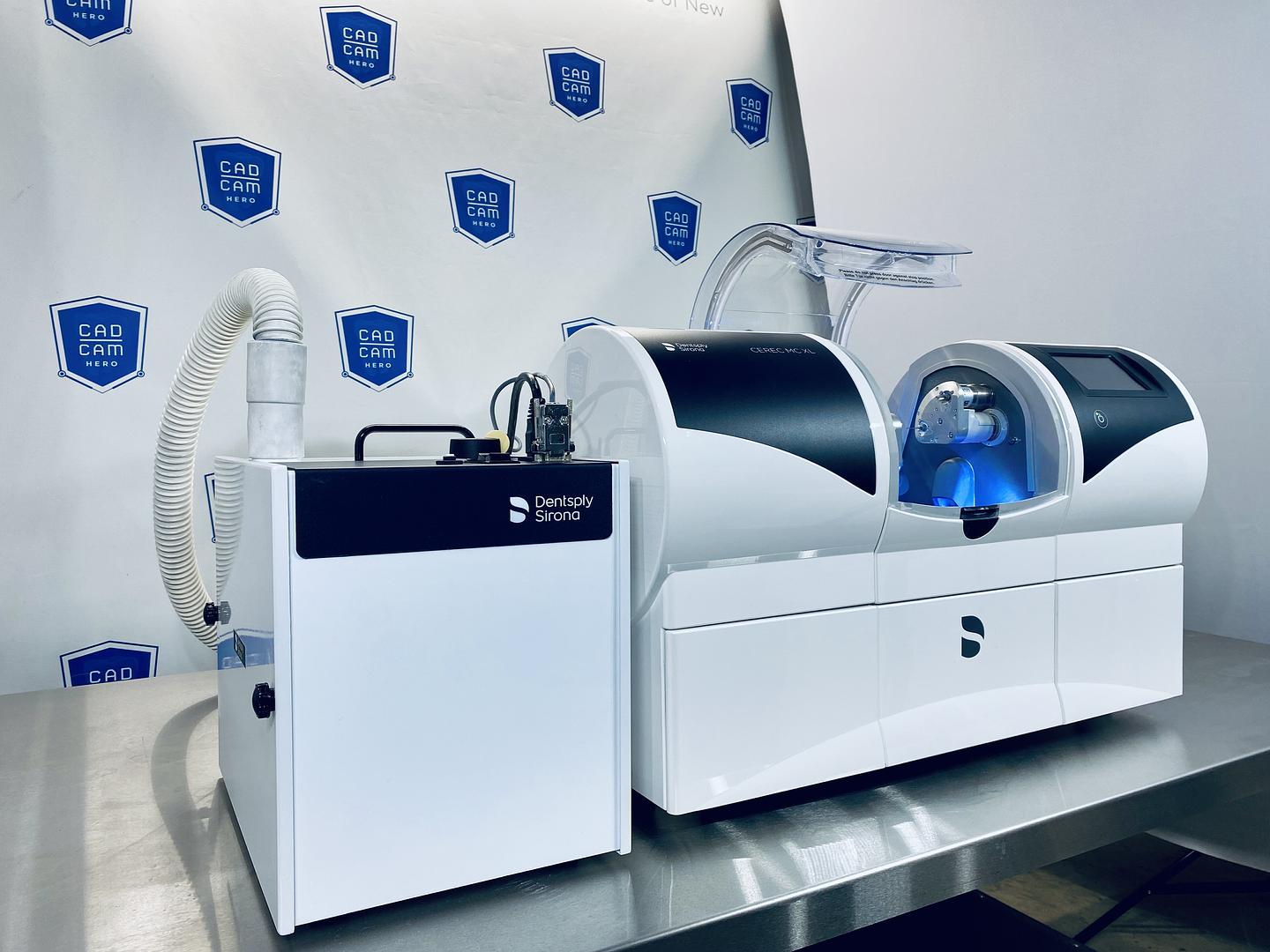

CAD/CAM inventory

Short on Cash? No Problem!

We have partnered with Reliant Capital to offer fast and competitive financing solutions to our customers. We will also work with any financial institution of your choice.

FINANCINGWhy Sell Your CEREC to CAD/CAM HERO?

Why Buy a CEREC from CAD/CAM HERO?

OUR REVIEWS

“This is a testimonial motivated by my recent experience of the services offered by Jhuri Lamica @ CAD/CAM HERO .My Cerec milling unit broke down. I had previously purchased some equipment from Jhuri and asked him to take a look at the unit. Such was my confidence in his abilities, that I shipped my unit from Ireland to Texas for the repair job. He quickly repaired and returned a working serviced unit to my busy dental surgery. Jhuri’s knowledge, experience and skill with CEREC units is unrivaled. I highly recommend him and look forward to continuing my practices relationship with CAD/CAM HERO long into the future.”

“Honestly, I was a little apprehensive wiring $19,000 to someone I found on the Internet and never met in person, but Jhuri Lamica with CAD/CAM HERO far exceeded my expectations. Everything was just as he said, and he did everything he said he would do…plus more. He spent over an hour on the phone with Sirona support working out a few kinks with the connection of my new milling machine. Now it’s working great! Jhuri is extremely knowledgeable about CEREC and just a phone call away. I highly recommend him if you’re looking to buy or sell any CEREC products.”